Over the years Merlin Engineering has been involved in many exciting projects and industries. Our expertise is wide ranging, machining Aluminium, Stainless Steel, Mild Steels, Brass and various Plastics. We also have a complete Fabrication section including coded Aluminium Welding.

Merlin Engineering have a clean assembly area, completely separated from the machine area, where we assemble, and wire complete machines to our customer’s specification.

Although at Merlin Engineering we are a sub-contract operation, we also engineer a complete Carton Feeder machine of our own for overprinting date codes and batch codes. We also have a range of components for Funeral Limousine manufacturers. Please see below for more information.

Labelling and Packaging Equipment

Over the years Merlin Engineering has been involved in many exciting projects and industries. Our expertise is wide ranging, machining Aluminium, Stainless Steel, Mild Steels, Brass and various Plastics. We also have a complete Fabrication section including coded Aluminium Welding.

Merlin Engineering have a clean assembly area, completely separated from the machine area, where we assemble, and wire complete machines to our customer’s specification.

Although at Merlin Engineering we are a sub-contract operation, we also engineer a complete Carton Feeder machine of our own for overprinting date codes and batch codes. We also have a range of components for Funeral Limousine manufacturers. Please see below for more information.

Manufacture of Components for the Print Proofing Industry

At Merlin Engineering, we specialise in the manufacture of components for the print proofing industry. These require highly accurate, visually appealing components made to the highest standards.

All our components are fully labelled with the part number, description and customer order number for easy identification once delivered.

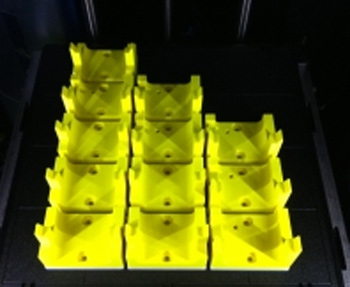

We can produce 3D prints in 9 different colours :

- FDM : ABS Plastic – 9 Colours to choose from

3D Printing / Additive Manufacturing

3D Printing from Merlin gives you the ability to easily test product designs using models made of various materials.

The Models are tough enough to be used as working parts.

Complex parts produced this way can be surprisingly cost effective, especially when comparing low volume to subtractive manufacturing methods.

Test Form, Fit And Function

You can make complex assemblies that work. Pieces formed by our Printers actually snap or fit together. The prototypes can withstand rigorous functional testing and retain their exact dimensions. Also, the models can be drilled, tapped, sanded, even painted.

Cut Weeks Off Your Design Cycle

Our printing could create prototypes in just hours – often ready next day.

Catch Flaws Before They Become Disasters

The quick, inexpensive models from our additive manufacturing machines allow designers to now efficiently model multiple concepts right from their desktop. Catching flaws early in the design process can save you thousands of pounds!

Full Design Service

3D Printing from Merlin gives you the ability to easily test product designs using models made of various materials.

The Models are tough enough to be used as working parts.

Complex parts produced this way can be surprisingly cost effective, especially when comparing low volume to subtractive manufacturing methods.

Parts Stock

Merlin hold a large inventory of customer stock, ready for immediate delivery. In agreement with our customers, parts can be put into our Kan-Ban system where replacements are automatically produced and held ready for despatch.

The customer can access our stock levels from this site to check availability. This also has the added advantage of paying a batch price for a one-off delivery when required – ideal for regular spare parts.

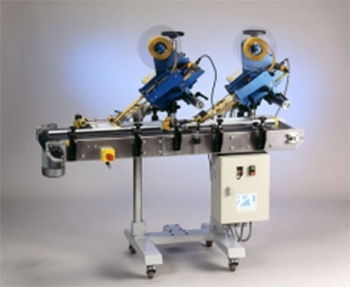

Carton Feeder

Our own design, the compact and robust, the M300 can handle cartons, sleeves, blister cards, leaflets and cut labels, including product with complex shapes. Product is transported from the hopper to the print head by a belt drive or vacuum drive giving excellent print registration. Rapid product changes can be accomplished quickly and easily with its adjustable feeder and position indicators. Parameters such as speed, index length and batch quantity are easily changed via the keypad. It is manufactured from stainless steel and anodised aluminium therefore meeting the demands of food and pharmaceutical industries.

Features

- High product throughput

- Batch counter

- Low foil warning

- Vacuum option

- Multiple printheads can be fitted

- Code readers, blob detectors, vision inspection and character readers can be fitted

- Product collator options including shingling conveyor

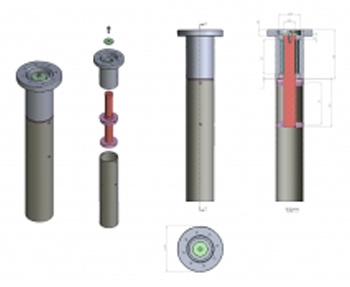

Limousine Deck Spares

We carry in stock, Adjustable Coffin Stop Assemblies and Single Posts, including rubber tyre for Funeral Cars and Hearses.